White carbon black drying project

Introduction of white carbon material

Silica is a generic term for white powder X-ray amorphous silicic acid and silicate products, mainly refers to precipitated silica, fumed silica, ultrafine silica gel and airgel, as well as powdered Synthetic aluminum silicate and calcium silicate. White carbon black is a porous material, its composition can be expressed in SiO2 · nH2O, where nH2O is in the form of surface hydroxyl. Soluble in caustic and hydrofluoric acid, insoluble in water, solvents and acids (except hydrofluoric acid). High temperature, nonflammable, tasteless, odorless, with good electrical insulation.

working principle

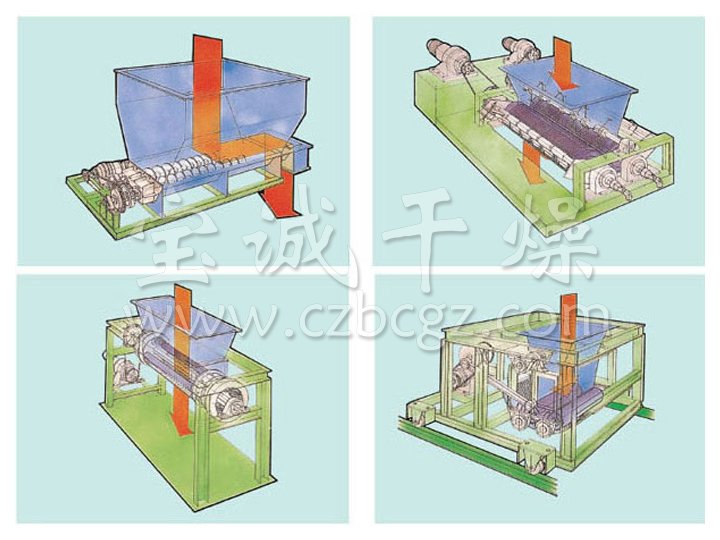

Hot air from the inlet tube at the appropriate jet speed from the bottom of the dryer into the mixing crushing drying room, the material produced a strong shear, blowing, rotating, so the material by centrifugation, shear, collision, friction and micro-granulation , Enhanced mass transfer heat transfer. At the bottom of the dryer, the larger and heavier particles are mechanically crushed under the action of a stirrer, the moisture content is low, the particles with smaller particle size are entrained by the rotating air stream and are further dried during the ascending process. As gas-solid two-phase rotation flow. Solid phase inertia is greater than the gas phase, the relative speed between the two phases of solid gas is relatively large, and the heat transfer between the two phases is enhanced. So the machine production of high strength.

- 2017-06-13 > How do we know the tank mixer?

- 2017-06-13 > Induction hot air circulation oven production characteristics

- 2017-02-27 > The working principle of double cone back vacuum dryer

- 2017-02-23 > Operation of double cone rotary vacuum dryer

- 2017-02-20 > Introduction of Double Cone Rotary Vacuum Dryer

- 2017-02-17 > Advantages of Double Cone Rotary Vacuum Dryer

- 2016-08-15 > Double cone rotary vacuum dryer with counterweight adjustment range