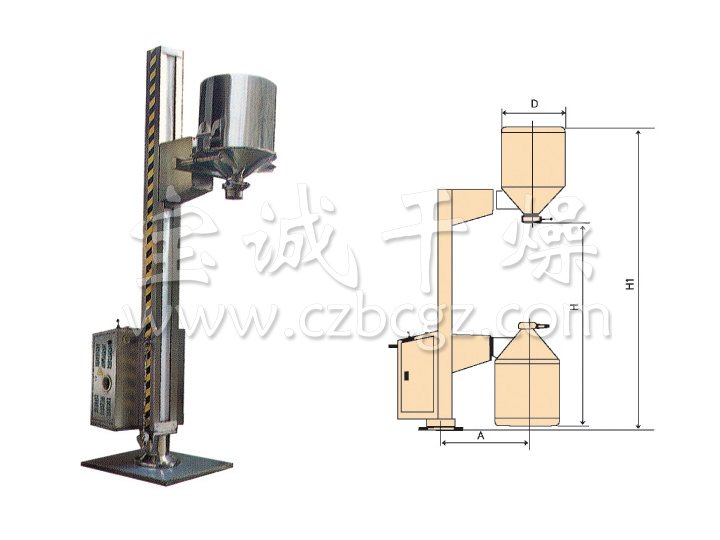

Stainless steel containers

DESCRIPTION

Such series of container are fit for thick/thin mixing of pharmacy industry, the tanker with interlining can heat, cool while the internal surface is eletrolytic mirror finished, the capped ends (taper) are spinning processed which applies GMP standard. The blender equipments apply sanitary mechanical sealing, the heat preservation of such containers adopts polyurethane or pearl cotton, the interfaces apply quick-fitting bar clasp style of international standard which is convenient and sanitary, the edges are spinning processed, the external surface applies grinding, sand blasting, frosted finish or cold rolling primary color matte processing, etc, that makes the container expresses its outstanding quality in any occasion. The device equips with air blowhole, CIP cleaning, blast finishing, sight glass, flange quick-opening manhole and other devices.

As the stockpiling capacity differs from 1000-15000L, the tanks with the stockpiling capacity over 20,000L are advised to be stocked outdoor, the tanks are manufactured using SUS304 stainless steel. According to the design requirements can be attached device type as follows:

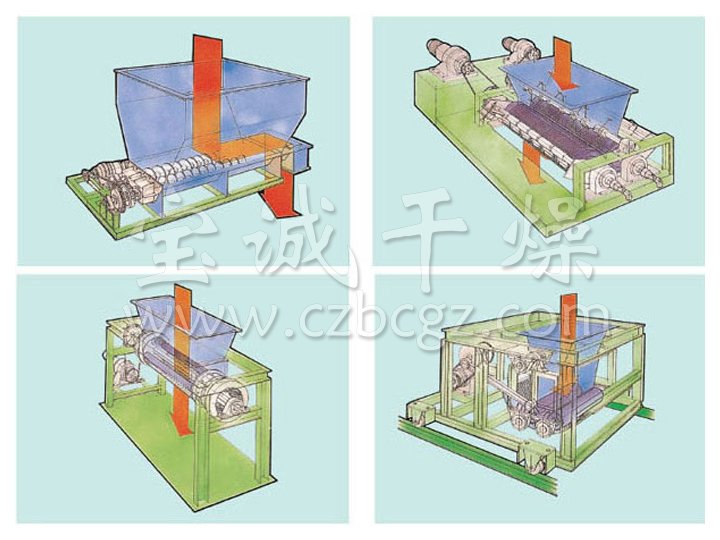

Blender

Feed port/ discharge hatch

Manhole

Thermometer

Liquid level indicator

High& low liquid level alarm hole

Fly& dust-resistant blowhole

Gauge

- 2017-06-13 > How do we know the tank mixer?

- 2017-06-13 > Induction hot air circulation oven production characteristics

- 2017-02-27 > The working principle of double cone back vacuum dryer

- 2017-02-23 > Operation of double cone rotary vacuum dryer

- 2017-02-20 > Introduction of Double Cone Rotary Vacuum Dryer

- 2017-02-17 > Advantages of Double Cone Rotary Vacuum Dryer

- 2016-08-15 > Double cone rotary vacuum dryer with counterweight adjustment range