The working principle of double cone back vacuum dryer

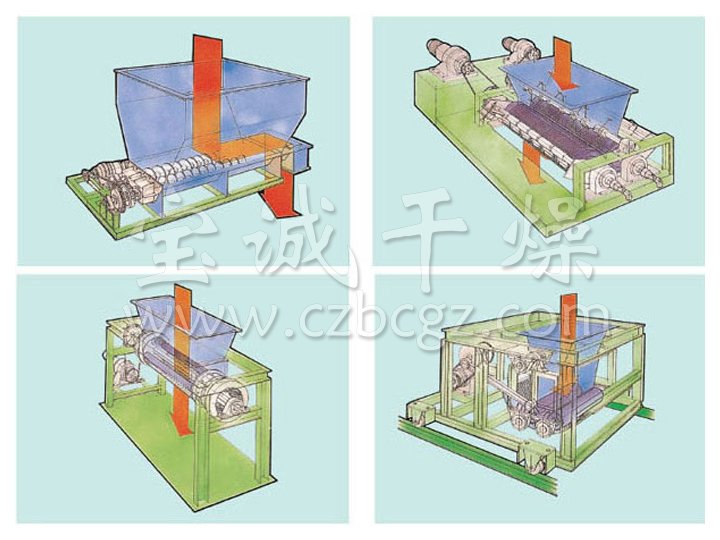

As the tank is in a vacuum state, the solvent (including water) in various materials can be rapidly vaporized at a lower temperature under vacuum conditions, and the rotation of the tank keeps the material up and down, inside and outside, and the material is continuously renewed And the wall contact with the surface, so as to make full use of the heat conduction wall, speed up the drying speed of materials, improve drying efficiency, and can achieve the purpose of uniform drying.

The solvent (vapor) evaporated by the wet material is absorbed by the vacuum pump through the vacuum pump. Through the low-temperature condensation system (using tap water or frozen brine) to cool, in order to achieve the purpose of recycling, saving production costs and improve the operating conditions of the vacuum pump, but also reduce the environmental pollution.

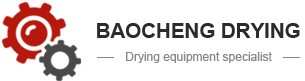

Changzhou Baocheng Drying Equipment Co., Ltd. specializes in the production of hot air circulation oven, double cone rotary vacuum dryer and other equipment, double cone rotary vacuum dryer stable performance, leading technology, design and production of double cone rotary vacuum dryer by the market recognition and customer Welcome, in the same product competition occupies a greater advantage, welcome to consult, Tel: 13775089889!

- 2017-06-13 > How do we know the tank mixer?

- 2017-06-13 > Induction hot air circulation oven production characteristics

- 2017-02-27 > The working principle of double cone back vacuum dryer

- 2017-02-23 > Operation of double cone rotary vacuum dryer

- 2017-02-20 > Introduction of Double Cone Rotary Vacuum Dryer

- 2017-02-17 > Advantages of Double Cone Rotary Vacuum Dryer

- 2016-08-15 > Double cone rotary vacuum dryer with counterweight adjustment range